Winged microchip: Scientists in the US build the smallest-ever human-made flying structure

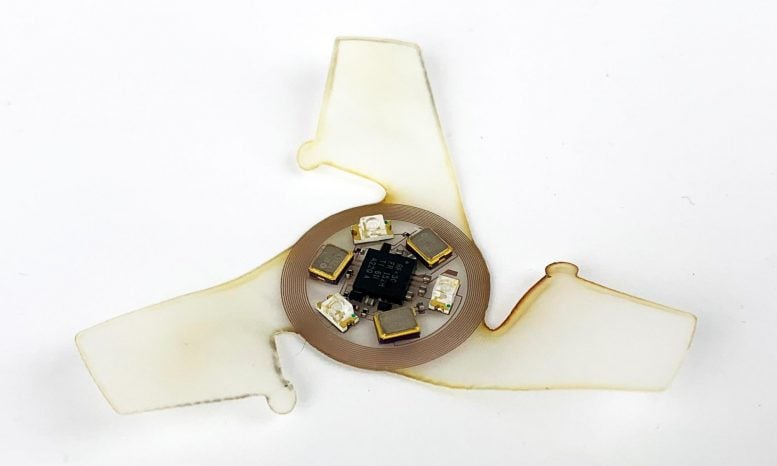

Electronic microchips now have a new capability to fly, thanks to Northwestern University engineers. The new flying microchip (or micro-flier) is about the size of a grain of sand. It lacks a motor or engine. Instead, it takes to the air like a maple tree’s propeller seed. It spins through the air like a helicopter […]

Electronic microchips now have a new capability to fly, thanks to Northwestern University engineers. The new flying microchip (or micro-flier) is about the size of a grain of sand. It lacks a motor or engine. Instead, it takes to the air like a maple tree’s propeller seed. It spins through the air like a helicopter toward the ground.

Engineers improved the micro-flier’s aerodynamics by examining maple trees and other types of wind-dispersed seeds. It is to ensure that it falls at a slow and controlled speed when dropped from a high altitude. This characteristic stabilizes its flight, assures dispersion over a large region, and extends the time it spends in the air. Thereby, making it perfect for monitoring air pollution and disease.

This micro flier can be packed with ultra-miniaturized technology. Such as sensors, power sources, antennae for wireless communication, and embedded memory to retain data, as they are the tiniest human-made flying structures ever.

The study is also a feature on the cover of Nature on September 23.

Micro-flier’s goal

“Our goal was to add a winged flight to small-scale electronic systems, with the idea that these capabilities would allow us to distribute highly functional, miniaturized electronic devices to sense the environment for contamination monitoring, population surveillance or disease tracking,” said Northwestern’s John A. Rogers, who led the device’s development. “We were able to do that using ideas inspired by the biological world. Over the course of billions of years, nature has designed seeds with very sophisticated aerodynamics. We borrowed those design concepts, adapted them, and applied them to electronic circuit platforms.”

Rogers is a pioneer in bioelectronics and the director of the Querrey Simpson Institute for Bioelectronics. He is the Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery in the McCormick School of Engineering and Feinberg School of Medicine. Yonggang Huang, the Jan, and Marcia Achenbach Professor of Mechanical Engineering at McCormick directed the study’s theoretical work.

Microflier catching the breeze

The whirling propeller seed of a maple leaf has been seen by most people spinning through the air and gently landing on the sidewalk. This is only one example of how nature has devised ingenious, intricate strategies to help plants survive. Otherwise sedentary plants and trees can propagate their species across huge distances. They occupy large areas by ensuring that seeds are extensively disseminated.

“Evolution was likely the driving force for the sophisticated aerodynamic properties exhibited by many classes of seeds,” Rogers said. “These biological structures are designed to fall slowly and in a controlled manner, so they can interact with wind patterns for the longest possible period of time. This feature maximizes lateral distribution via purely passive, airborne mechanisms.”

The Northwestern team investigated the aerodynamics of a variety of plant seeds to create the micro-fliers; the Tristellateia plant, a flowering vine with star-shaped seeds, providing the most direct inspiration. Seeds of Tristellateia feature bladed wings that catch the wind and fall with a slow, spinning spicule.

‘We think that we beat nature’

Rogers and his team created a variety of micro-fliers. Micro-flier includes one with three wings that tune to resemble the forms and angles of Tristellateia seed wings. Huang led full-scale computational modeling; of how air flows around the device to emulate the Tristellateia seed’s slow; controlled rotation to determine the most optimal configuration.

“The computational modeling allows a rapid design optimization of the fly structures that yields the smallest terminal velocity,” Huang said. “This is impossible with trial-and-error experiments.”

In partnership with Leonardo Chamorro, an associate professor of mechanical engineering at the University of Illinois in Urbana-Champaign, Rogers’ group then created and tested structures in the lab using new technologies for imaging and quantifying flow patterns.

The resulting structures can be in a wide range of sizes and shapes, with some possessing qualities that rival those of nature.

“We think that we beat nature,” Rogers said. “At least in the narrow sense that we have been able to build structures that fall with more stable trajectories and at slower terminal velocities than equivalent seeds that you would see from plants or trees. We also were able to build these helicopter flying structures at sizes much smaller than those found in nature. That’s important because device miniaturization represents the dominating development trajectory in the electronics industry, where sensors, radios, batteries, and other components can be constructed in ever-smaller dimensions.”

From plants to pop-up books

Rogers’ team got the inspiration for the devices from another well-known novelty: a children’s pop-up book.

His team began by fabricating flat, planar shapes as antecedents to flying structures. The precursors then attach to a somewhat stretched rubber substrate. When the stretched substrate relaxes, the wings “pop up” into precisely specified three-dimensional structures. It is due to a controlled buckling process.

“This strategy of building 3D structures from 2D precursors is powerful because all existing semiconductor devices are built-in planar layouts,” Rogers said. “We can thus exploit the most advanced materials and manufacturing methods used by the consumer electronics industry to make completely standard, flat, chip-like designs. Then, we just transform them into 3D flying shapes by principles that are similar to those of a pop-up book.”

Microflier packed with promise

The micro-flier consists of two parts: electrical functioning components that are of millimeter size and their wings. The micro-flier wings’ interact with the air as it falls through the air, creating a steady, stable circular motion. The electronics distribute low in the middle of the micro flier. It is to prevent it from losing control and plummeting to the earth in a haphazard manner.

Rogers’ team used sensors, a power source that can harvest ambient energy, memory storage. An antenna to wirelessly transport data to a smartphone, tablet, or computer in their demonstrations.

To detect particles in the air, Rogers’ group outfitted one device with all of these elements in the lab. They also included pH sensors to check water quality. Also, photodetectors evaluate light exposure at various wavelengths in another example.

Rogers envisions a huge number of devices dropped from a plane or building. Then, scattered widely to track environmental remediation activities following a chemical spill or to detect air pollution levels at various altitudes.

“Most monitoring technologies involve bulk instrumentation designed to collect data locally at a small number of locations across a spatial area of interest,” Rogers said. “We envision a large multiplicity of miniaturized sensors that can be distributed at a high spatial density over large areas, to form a wireless network.”

Disappearing act

But what about electronic trash? Rogers has a strategy in place to deal with this. As in the recent work on bioresorbable pacemakers, his group already makes transitory electronics that can dissolve harmlessly in water once they are no longer useful. His team is now utilizing the same materials and procedures to create micro-fliers that decay naturally in groundwater and vanish over time.

“We fabricate such physically transient electronics systems using degradable polymers, compostable conductors, and dissolvable integrated circuit chips that naturally vanish into environmentally benign end products when exposed to water,” Roger said. “We recognize that recovery of large collections of micro-fliers might be difficult. To address this concern, these environmentally resorbable versions dissolve naturally and harmlessly.”

The Querrey Simpson Institute for Bioelectronics at Northwestern University funded the work, titled “Three-dimensional electronic micro-fliers inspired by wind-dispersed seeds”. Co-corresponding authors include Leonardo Chamorro of the University of Illinois and Yihui Zhang of Tsinghua University in China, in addition to Rogers and Huang. Bong Hoon Kim of Soongsil University in Korea, Kan Li of Huazhong University of Science and Technology in China, and Jin-Tae Kim and Yoonseok Park, both of Rogers’ group at Northwestern, are the paper’s first authors.

This article Winged microchip: Scientists in the US build the smallest-ever human-made flying structure appeared first on BreezyScroll.

Read more on BreezyScroll.